Clinker Grinding Quartz

.jpg)

Effects of Fineness and Morphology of Quartz in

2024年7月21日 This study investigates the influence of the quartz content and particle size in siliceous limestone on the calcination process and the resultant quality of cement clinker Two different siliceous limestones were grinded to 1991年9月1日 Excessive shell and ball coatings led to virtual stoppage of fine grinding of cement clinker and limestone Quartz, which did not exhibit this property, continued to grind finer All The effect of grinding aids on the fine grinding of limestone, quartz 1991年9月1日 Excessive shell and ball coatings led to virtual stoppage of fine grinding of cement clinker and limestone Quartz, which did not exhibit this property, continued to grind finer All The effect of grinding aids on the fine grinding of limestone, quartz Three key outcomes of this study provide new insights on the use of siliceous limestone in cement production, namely that (i) reducing the fineness values of siliceous limestone from 15% to 0% Effects of Fineness and Morphology of Quartz in Siliceous

Effects of Fineness and Morphology of Quartz in Siliceous

2024年7月21日 With the increasing depletion of highquality raw materials, siliceous limestone, sandstone and other hardtoburn raw materials containing crystalline SiO 2 are gradually 2024年4月17日 Based on the preliminary experiments, 5 g of clinker was pulverised for 2 h for drygrinding and methanol solution (6 mL) was added for wetgrinding program In more detail, Investigation on the MicroGrinding Induced 2020年7月1日 The results of the study of the grinding capacity of clinker grains show that their mechanical properties are determined by the size, shape, composition, spatial orientation and Influence of Clinker Microstructure on Grinding Efficiency in 2020年7月31日 Numerous experiments on the study of the kinetics of dispersion of mineral rocks show that grinding in laboratory mills can predict the evolution of particle sizes Influence of Clinker Microstructure on Grinding Efficiency in

.jpg)

The effect of grinding aids on the fine grinding of limestone, quartz

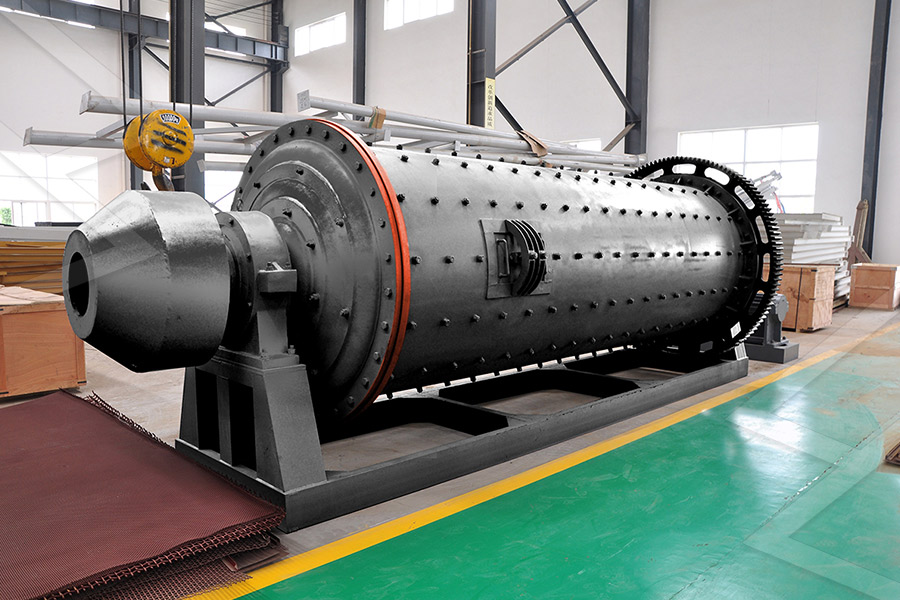

1991年9月1日 Grinding aids (GAs) are polar chemicals introduced in cement mills in either liquid or powder form to improve on mill grindability efficiency Studies have shown that some GAs 2020年7月31日 The action mechanism of surfactants and increasing the efficiency of grinding mineral powders have been repeatedly studied and discussed In some works, the action mechanism of surfactants is explained from the point of view of the Rebinder theory (Rebinder effect) [1, 2], in other works, the effect of surfactants is reduced only to a decrease in the Influence of Clinker Microstructure on Grinding Efficiency in 1991年9月1日 The initial stages of grinding of the materials studied, without the use of grinding aids, were found to depend on their Moh's hardness Excessive shell and ball coatings led to virtual stoppage of fine grinding of cement clinker and limestone Quartz, which did not exhibit this property, continued to grind finerThe effect of grinding aids on the fine grinding of limestone, quartz Grinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Clrm Series Calcium Carbonate Gypsum Limestone Limestone Roller Mill for Sale in Iran, CLUM Series Ultrafine Vertical Roller Mill PE Jaw Crusher with Cheaper Price for Calcium Carbonate Gypsum Limestone Marble Mica Dolomite Powder Production Line, Clrm Series Low Cost Gypsum Raymond mill; Superfine grinding mill; Vertical roller mill

.jpg)

Air Separation System,Clinker Grinding Unit Exporters

Sama Engineering Works Shara Pur Village Road, West Roorkee Road, Roorkee Road, Muzaffarnagar, Uttar Pradesh , India Mobile : +91, +91023年10月23日 In this study we compare the effects of three different grinding aids on clinker grinding using a ball mill A commercial grinding additive, triethanolamine (TEA), and two industrial grinding aids (GAA079 and GAA088) were compared by ball milling tests, with additions of 005, 025, 050 and 100 wt% High quartz content in clay [PDF] A study of different grinding aids for lowenergy cement clinker 2024年5月14日 To achieve optimal clinker grinding, it is essential to implement effective strategies that can enhance the process and improve overall efficiency One strategy is to carefully monitor and control the grinding parameters such as mill speed, ball size, and grinding media density Adjusting these parameters can help achieve the desired fineness Cracking the Code: The Mystery Behind Why Clinker is Hard to Grind1983年1月1日 The range of clinker composition may be fairly wide if the amount of liquid phase increases slowly [55] A clinker with about 25% liquid phase from a raw mix is generally considered an ideal raw mix for kiln lining, fuel saving, rapid C3S formation through dissolution of C2S and CaOr and economical clinker grindingBurnability and Clinkerization of Cement Raw Mixes

.jpg)

Improving the Behaviour of Calcined Clay as Supplementary

2020年4月14日 Grinding aids (GAs) are incorporated during comminution of clinker to reduce electrostatic forces and minimize agglomeration of clinker and SCM grains Such additions are commonly used to increase cement fineness and compressive strength for given specific energy consumption (Ec) of the grinding mill [ 1 , 2 , 3 ]With the increasing depletion of highquality raw materials, siliceous limestone, sandstone and other hardtoburn raw materials containing crystalline SiO2 are gradually being used to produce clinker This study investigates the influence of the quartz content and particle size in siliceous limestone on the calcination process and the resultant quality of cement Effects of Fineness and Morphology of Quartz in Siliceous 2024年7月31日 The production of cement, an essential material in civil engineering, requires a substantial energy input, with a significant portion of this energy consumed during the grinding stage This study addresses the gap in the literature concerning the collective impact of key parameters, including ball size, feed rate, and mill speed, on grinding efficiency Nine spherical Effect of Grinding Conditions on Clinker Grinding Efficiency 2019年12月1日 The production of fine particles in the lower micron range by dry grinding processes demands large amounts of energy For instance, the cement industry alone consumes approximately 12–15% of the world’s total industrial energy, whereby the fine finish grinding of the cementitious products accounts for about 30% of the overall energy consumption (Madlool, Comparative study of the grinding aid effects for dry fine grinding

.jpg)

Influence Grinding Procedure, Limestone Content and PSD

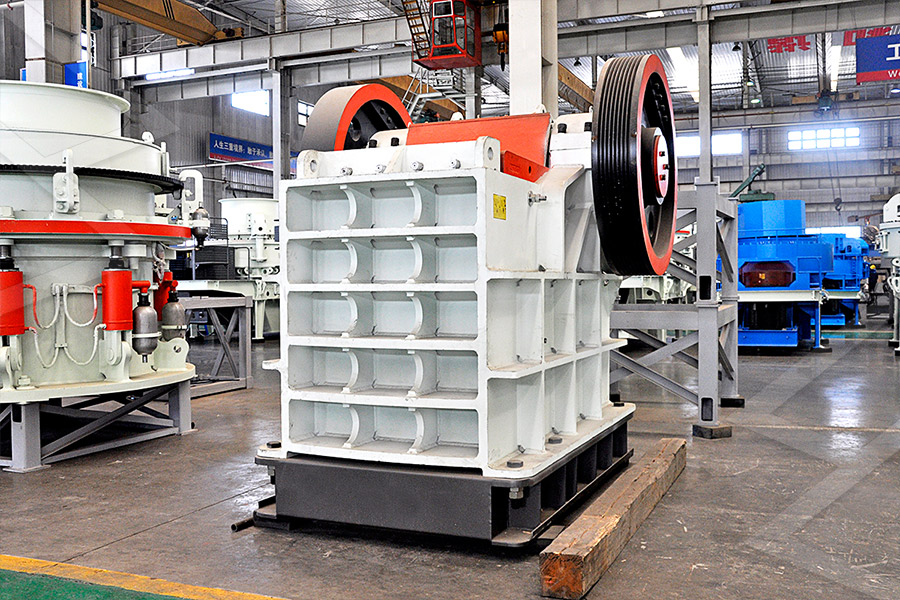

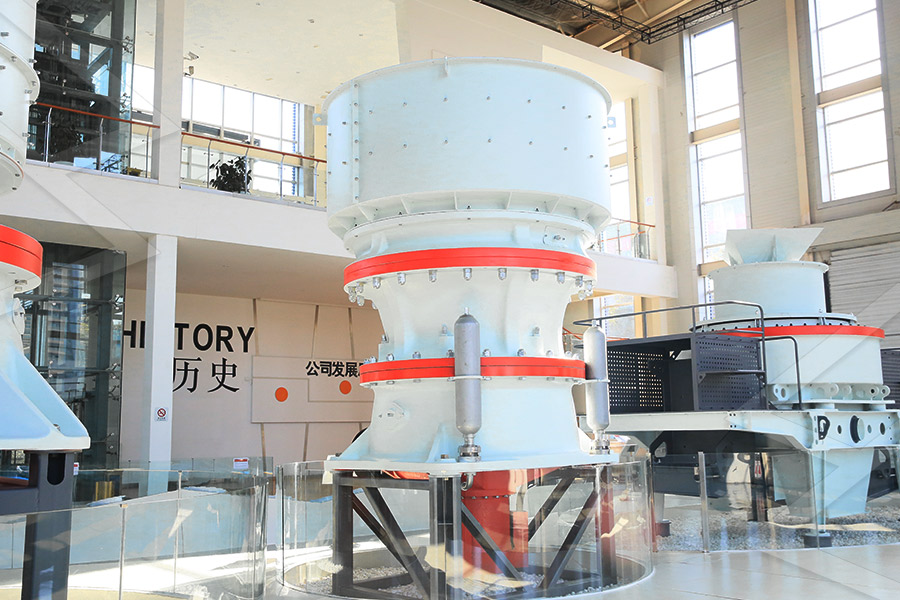

2017年10月28日 Concrete is the most widely used material on earth; It is strong, durable and relatively inexpensive The cement industry is responsible for about 5–8% of the global manmade CO 2 emissions On average 08–09 tons CO 2 is emitted for the production of 1 ton of cement During the production of cement clinker, calcium carbonate from limestone decomposes to 2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLinkCement Clinker Grinding Mill The cement clinker uses limestone, clay, and iron as the main raw materials, and is prepared into a raw material at an appropriate ratio, and is partially or completely melted and cooled to obtain a semifinished product In the cement industry, the most commonly used is portland cement clinkerCement Clinker Grinding Mill, cement clinker mill, cement clinker 2023年11月6日 Experimentally, it was revealed that a cement mixture with a lower amount of clinker, and ground along with a grinding aid produced a cement product that had a higher compressive strength than the standard mixture Therefore, it reveals that incorporation of GAs in cement grinding has added advantage of reducing the clinker factor and thereby Review of the Effect of Grinding Aids and Admixtures on the

.jpg)

Study Of The Clinker Characteristics And Grindability During

The grinding of clinker depends on the chemical composition and mineralogical properties; high content of alite and low content of belite and interstitial phases (aluminate and ferrite) is easier to grind than the clinker rich in belite and interstitial phases densely packed crystals due to coarse quartz in feed causing hard clinker and DOI: 101016/japt202009028 Corpus ID: ; Effects of mechanical grinding on pozzolanic activity and hydration properties of quartz @article{Yao2020EffectsOM, title={Effects of mechanical grinding on pozzolanic activity and hydration properties of quartz}, author={Geng Yao and Tao Cui and Jiakang Zhang and Junxiang Wang and Xianjun Lyu}, Effects of mechanical grinding on pozzolanic activity and 2016年7月13日 The use of a good Cement clinker grinding aid can be vital in today's increasing material demands Along with the obligation to process increasingly larger other than cement clinker has also been reported These include, among other instances, the use of wool grease in the grinding of gypsum, limestone, and quartz (Hobday, 1946; Voznyuk Cement Clinker Grinding Aids 911Metallurgist2024年7月31日 Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate Quartz (1080–1168 g) and copper waste (792–949 g) Quartz (03–16 mm(PDF) Effect of Grinding Conditions on Clinker Grinding

Grinding aids for dry fine grinding processes ScienceDirect

2020年9月20日 Scheibe et al [25] carried out an extensive investigation of various grinding aids on the batchwise grinding of cement clinker, quartz and limestone in the 1970s They found that the impacts of the applied chemical on parameters like the product fineness or the material adhesions inside the mill depend on a complex relation between the ground 2024年10月18日 Clinker Calcium Carbonate Dolomite Barite Quartz Marble Limestone Dust Making Machine Raymond Grinding Mill Plant, Find Details and Price about Grinding Machine Mill Machine from Clinker Calcium Carbonate Clinker Calcium Carbonate Dolomite Barite 2020年7月1日 In the literature, a similar situation has been observed in the positive effects of the moisture content on grinding As is well known, water (humidity 35%) is a polar substance and can cause Grinding aids for dry fine grinding processes – Part I: Mechanism 2019年4月29日 In this study, quartz, marble, quartzite, and metasandstone with densities 265, 272, 259, and 211 t/m 3, respectively, were used as test materialsThe origin of the materials as well as their physicomechanical properties are described in recent study []The grinding tests were performed in a laboratory 0204 × 0166 m (D × L) ball mill that operated at 66 rpm Effect of Energy Input in a Ball Mill on Dimensional

Effect of Quartz in Clay on Grindability of Raw Semantic

2022年8月25日 High quartz content in clay substantially impacts the grinding of raw mix, quality of clinker and final cement produced The presence of quartz requires very fine grinding and a long sintering time to react significantly, all of which are very expensive This study assessed an extensive plant sample which involved a vertical roller mill to determine the correlation 2017年6月15日 Based on clinker grinding we put forth a simple correlation to relate grinding energy consumption in kWh for the particle size in microns which adequately describes the data on likewise systems from ball milling technique for ferric oxide, zinc oxide810 quartz ultra fine to nano particles : E d p = 240(4)Design and Optimization of Ball Mill for Clinker Grinding 2020年12月30日 Schoni et al [14] performed batch grinding tests with quartz, limestone and Portland cement clinker and examined the performance of seven different GAs While GAs did not affect the grinding performance of quartz, grinding efficiency of limestone and clinker was improved thanks to GAsEffects of grinding aid dosage on circuit performance and 2023年10月1日 Deniz studied investigates the effect of milling speed on the kinetic breakage parameters for clinker and limestone during grinding On this basis, the effects of grinding aids on the kinetic parameters for quartz grinding with scanning electron microscopy, specific surface area and contact angle determinations to probe the surface Effects of grinding aids on the grinding kinetics and surface

[PDF] Effects of Fineness and Morphology of Quartz in

2024年7月1日 With the increasing depletion of highquality raw materials, siliceous limestone, sandstone and other hardtoburn raw materials containing crystalline SiO2 are gradually being used to produce clinker This study investigates the influence of the quartz content and particle size in siliceous limestone on the calcination process and the resultant quality of cement 2021年8月18日 Due to coarse quartz grains in feed, pores are surrounded by belite grains (CLN and CLW) which adversely affect the grinding properties of clinker Fewer microcracks present in alite of CLN can be attributed to a rapid crystallization of the matrix[ 40 ChemicoMineralogical Evaluation of Clinker from Four2020年7月1日 While the grinding aids had only a marginal effect on the grinding of quartz, they had a significantly beneficial effect on the grinding of limestone and cement clinkerInfluence of Clinker Microstructure on Grinding Efficiency in 3 天之前 Dry Clinker Grinding Station Limestone Stone Slag Cement Ball Mill US$6,50000200,00000 / set: 1 set (MOQ) for various hard and brittle materials such as rocks, cement clinker, quartz, iron ore and concrete Dry Clinker Grinding Station Limestone Stone

.jpg)

:: SABKO Industries :: Rotary Kiln, Rotary Kiln

2014年6月16日 With over 50 years of existence in the Industry, Today, Sabko Industries Group has one of the widest Indian offering of Cement Plants, Rotary Kiln and Vertical Shaft Kilns, Lime Kilns, grinding mills emery stone, mineral The quartz ball mill can be used to grind different types of quartz minerals, such as quartzite, sand stone and quartz sand In addition to quartz mineral, the quartz ball mill can also grind raw meal, cement clinker and other types of mineral raw materials, and has the same functions as cement ball mill and ore ball mill Quartz sand is an Quartz Ball Mill Quartz Sand Ball Mill for Quartz Mineral Grinding2020年7月24日 This paper presents results regarding the grinding behaviour of two batches of material (clinker) in a ball mill with its own twostep grinding process: the first one with a ball load, the second Determination of granulometrical composition of the clinker by grinding 2001年1月15日 A desired amount of quartz sample (865 g) and additives were added to the pot filled with the grinding media All the experiments were conducted in a batchwise closed system under the grinding conditions shown in Table 2After grinding for a required time, the specific surface area of the ground products sampled by cone and quartering was measured by the The effect of liquid additives on dry ultrafine grinding of quartz

.jpg)

Granulometry of clinker PDF SlideShare

2012年3月8日 “The Influence of Coarse Quartz in Kiln Feed on the Quality of Clinker and Cement, Proceedings of the Seventh International Conference on Cement Microscopy, 1985, pages 1023 Since a substantial amount of energy expended at a cement plant is needed for clinker grinding, improvement in clinker grindability would increase grinding 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to Powder2019年2月15日 Sohoni et al [14] investigated the influences of seven grinding aids on the batch grinding of limestone, Portland cement clinker and quartz It was observed that the grinding aids had only a negligible impact on grinding of quartz although they had a considerably beneficial effect on the grinding of clinker and limestoneEffects of grinding aids on model parameters of a cement 2013年2月1日 Semantic Scholar extracted view of "The effects of grinding media shapes on the grinding kinetics of cement clinker in ball mill" by H Qian et al The kinetics of batch grinding quartz from a feed of 600 by 425 mm to a product of 80% less than 10 mm have been determined using screening and laser diffractometer sizing for size analysis The The effects of grinding media shapes on the grinding