Effect Of Ore Vs Balls In A Ball Mill

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral 2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls (PDF) Effects of Ball Size Distribution and Mill Speed and 2021年3月27日 In this article, alternative forms of optimizing the milling ef ciency of a laboratory scale ball mill by fi varying the grinding media size distribution and the feed material particle Effect of ball and feed particle size distribution on the

Understanding fine ore breakage in a laboratory scale ball mill using

2011年2月1日 However, it is now feasible to model a periodic section of a laboratory scale ball mill and include the coarser end of the ore size distribution directly in the DEM model This 2018年2月1日 In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle sizeEffect of ball and feed particle size distribution 2022年1月1日 Firstorder grinding kinetics exists for ball mills A correlation exists between specific impact energy and grinding rate constant Grinding efficiency decreases with Impact energy of particles in ball mills based on DEM simulations 2022年3月22日 ball mill employs steel balls to generate a grinding action, ie ore particle comminution via impact and abrasion with steel balls, and is a key component of benefi Effect of grinding media on the milling efficiency of a

.jpg)

Effect of ore heterogeneity on the ball mill wear rate

2023年7月11日 The current research aims to study the effect of gold ore grinding on the wear rate of grinding balls Methods Six boulder rock samples were selected from some KSA 2016年1月1日 The wear of balls used during a grinding process is considered one of the losses that cause an increase in the operating cost allocated to the ball mill [21](PDF) A comparison of wear rates of ball mill 2017年10月26日 a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account As well, mills with different length to diameter ratios for a given power rating will yield different material Factors Affecting Ball Mill Grinding Efficiency 911Metallurgist2024年8月8日 In this process, a powder mixture is placed in a rotating drum, along with grinding media such as balls The kinetic energy imparted by the balls' motion breaks the powder into smaller pieces, making it a critical technique in Ball Mill Success: A StepbyStep Guide to

Effect of grinding media on the milling efficiency of a ball mill

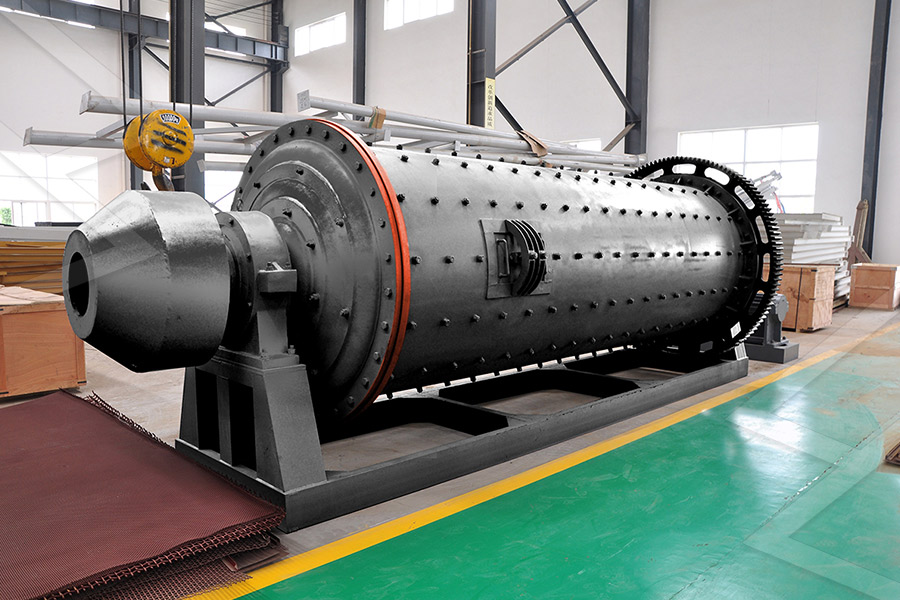

2022年2月14日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power consumption and particle size breakage) This article tackles the lack of a design tool that could help choose the ball loading composition in mills Such a tool enables the maximization of the exposed surface area per unit energy (cm2/J) The effect of 2024年9月24日 Investigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum The mill ball loading was 40% by volume, the rotation rate was equal to 85% of the critical speed Balls were made from steel: S4146, extra high quality, having hardness 62 ± 2 HRC according to RockwellTHE OPTIMAL BALL DIAMETER IN A MILL 911 2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

Consumption of steel grinding media in mills – A review

2013年8月1日 Apart from these cost factors, one of the major unsolved problems in the optimal design of ball mills concerns the equilibrium media size distribution in the mill, which is determined by the rate at which makeup media is added to the mill, as well as the rate at which these grinding media are consumed (Austin and Klimpel, 1985)Reliable prediction of grinding media 2019年8月15日 In this study eggshells and low density polyethylene plastic (LDPE) wastes were reused to produce tiles The eggshells were ground in a laboratory scale jar mill into the particle size of fine sand(PDF) Effect of interstitial filling, ball and feed size on particle 2017年10月18日 The abrasion test was chosen to simulate the abrasive wear that results from contact between ore and balls in ball mills No corrosion tests were run because corrosion effects in large ball mills are normally small relative to abrasion Ballonball repeated impact test The ballonball impactspalling apparatus, Fig 3, provided large numbers Grinding Ball Wear Breakage by Impact Abrasion Tests2022年3月15日 As a result, calculating power (or energy) is one of the essential factors in estimating operating costs and determining the best operating conditions for ball mills [4] Various operational Power consumption management and

The Influence of the Grinding Media Diameter

2024年6月14日 The grinding process plays a crucial role in industry, allowing for the reduction of particle sizes of raw materials and substances to the required fineness—either as a finished product or for further technological processes 2022年1月1日 Grinding experiments were conducted using a laboratory ball mill with copper sulphide ore The d80 and the amount of −37 μm fraction in the product were defined as process responses to model Effect of grinding media on the milling efficiency of a ball mill2024年2月19日 It directly affects the grinding effect and the degree of refinement of the ore When selecting ball mill steel balls, you need to consider the following factors: 1 The impact force of the steel ball and the number of effects depends on the ball diameter of the ball mill For materials that are difficult to grind, it requires a strong Ball Mill Steel Balls: Quality And Gradation JXSC Mineral2023年6月27日 explored the spectrum of collisional energy in ball mills The authors observed that the operational conditions of the mill signicantly changed the energy distribution over the load in the equipment Silva et al (2019) quantied the number and the intensity of the collisions in a dryer with inert bed, to different speeds of bed rotationExperimental study of clinker grinding in a ball mill and

.jpg)

Grinding Media in Ball Mills for Mineral Processing

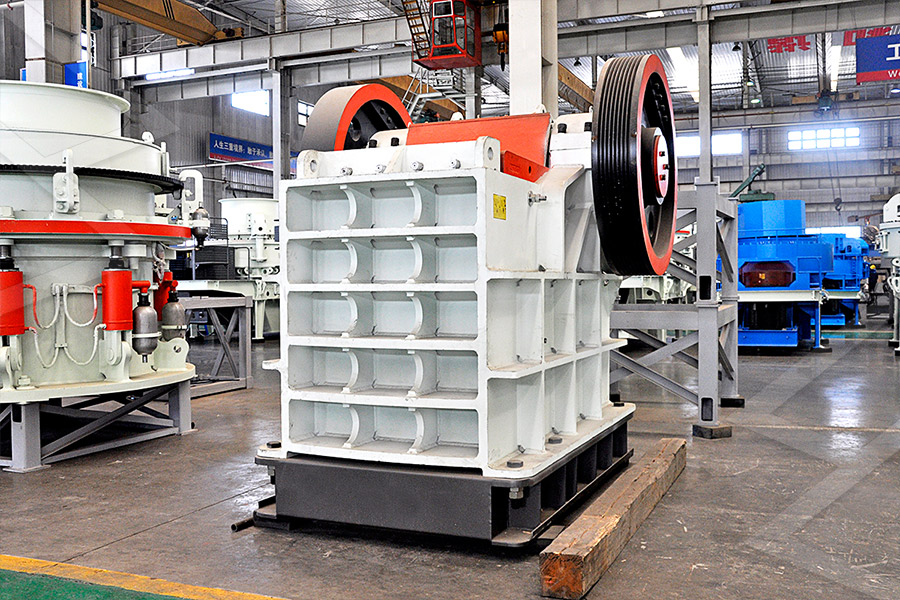

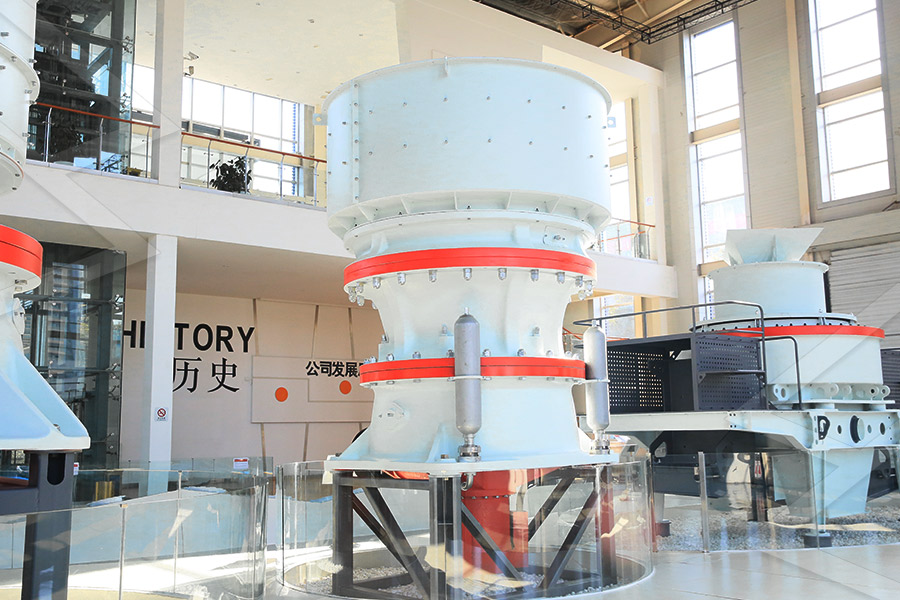

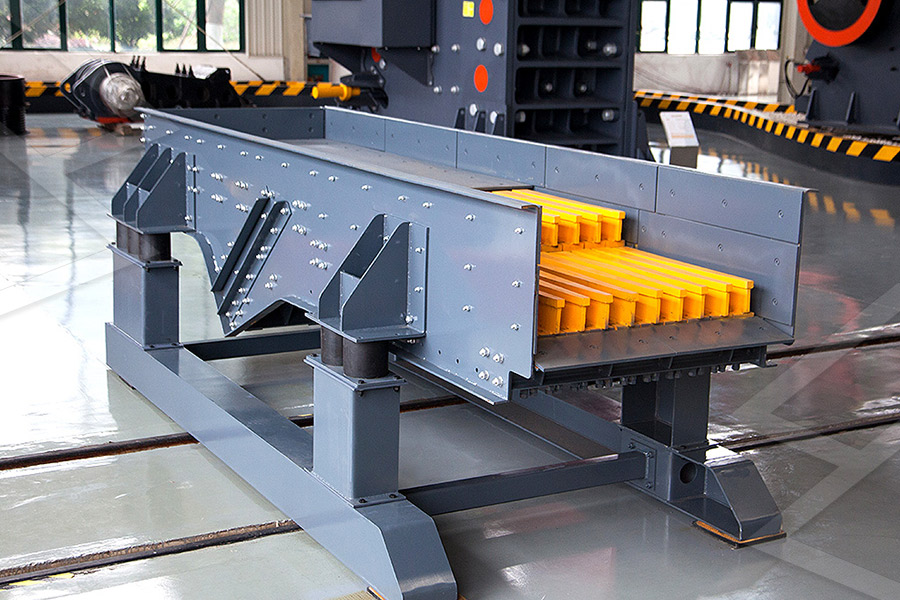

2023年11月24日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles and breakage kinetics parameters Usually, larger balls grind coarser ore particles efficiently and smaller balls grind fine particles and lastly spherical balls 43 Effect of Grinding Media Density on Mill In this study, we investigate the effect of drop weight shape, bed mass and drop height on the impact breakage of a runofmine platinum group metals (PGM) ore collected from the Great Dyke region 3: Mode of operation of a ball mill Download Scientific 2024年7月12日 A ball mill and a tumbling mill are both types of grinding mills used to reduce material size We mainly use a ball mill for mixing and grinding processes In contrast, we generally use a tumbling mill for finer material reduction What are the balls? Ball mills grind materials into an extremely fine formWhat Is a Ball Mill and How Does It Work? (Overview 2024)Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to reduce Ball Mill (Ball Mills Explained) saVRee saVRee

Effect of Energy Input in a Ball Mill on Dimensional

2019年4月29日 Two series of tests were carried out in order to study the properties of the grinding products under different operating conditions In the first series, quartz and marble were used as test materials and the effect of three different interstitial fillings U of 50%, 100%, and 150%, corresponding to ball filling volume J of 20%, 10%, and 67%, respectively, at a 2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the Ball Mills 911Metallurgist2023年9月1日 The observed effect of slurry density variations on ball load and mill absorbed power can be used to build a slurry density estimation model Effect of Slurry Density on Load Dynamic and Milling Ball Mill Online Estimation of Inmill Slurry Density2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls (PDF) Performance optimization of an industrial ball mill for

.jpg)

Effect of ball and feed particle size distribution on the milling

2018年6月1日 A number of researchers (Deniz, 2012; Bwalya et al, 2014; Petrakis et al, 2016) carried out studies about the effect of feed particle size and grinding media size on the grinding kinetics of different oresKhumalo et al, 2006 postulated that generally larger sized grinding media would break larger particles quicker but a finer product would be obtained by use of 2017年7月3日 If it is desired to find the effect of balls grinding 20mesh ore and the mill is loaded with 20mesh material, the grinding time should be infinitely short, because fine particles are made as soon as the mill starts and if the run continues the test is of the comminuted products of the 20mesh sample rather than that which was supplied for the Why use Different Size Balls in a Mill 911Metallurgist2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing 2016年6月6日 These mills typically grind ROM ore in a single stage A large example of such a mill was converted from a singlestage milling application to a semi autogenous ballmillcrushing circuit, and the application is well described This refers to highaspect AG/SAG mills Ball Charge Motion inside a SAG Mill With a higher density mill chargeSAG Mill Grinding Circuit Design 911Metallurgist

A Review of Advanced Ball Mill Modelling JSTAGE

Keywords: modeling, discrete element method, ball mills, mechanistic 1 Introduction In spite of the development and increase in popularity of several other technologies, such as vertical roller mills, stirred media mills and highpressure grinding rolls, ball mills still retain a significant part of their importance inThe effect of scats on ballmill productivity was tested and it was concluded that scats may not have an adverse effect on productivity in secondary ballmills and composite mills, if large balls SAG mill compared to crusher and ball mill product size 2022年3月22日 ball mill employs steel balls to generate a grinding action, ie ore particle comminution via impact and abrasion with steel balls, and is a key component of beneficiation plant production Even though it has massive benefits, such as a high reduction ratio, effective breakage impact, and a wide application (Fuerstenau andEffect of grinding media on the milling efficiency of a 2022年1月1日 The operation process of comminution has been studied in the past based on data gathered from various ores and semiempirical models [2]The pioneer of the study was Bond and the equation proposed by him is known as the Bond's grinding equation [3, 4]As the Bond equation did not consider breakage kinetics, all the effects in grinding were lumped into Impact energy of particles in ball mills based on DEM simulations

Friction and wear of liner and grinding ball in iron ore ball mill

2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Initial tests were done using pebbles from previous tests on gold ore, in combination with balls, to mill silica sand (0615 mm) The size distributions of the balls and the pebbles were calculated to simulate steadystate addition of balls (375 mm) and partlyrounded pebbles (1975 mm) The effect of ball size on mill performance Powder (PDF) Grinding Media in Ball MillsA Review Academia2012年4月17日 Effect of Slurry Density on Load Dynamic and Milling Performances in an Iron Ore Ball Mill Online Estimation of Inmill Slurry Density April 2012 DOI: 1013140/2146258561(PDF) Effect of Slurry Density on Load Dynamic and2015年4月16日 a mill grindout (no ore feed) of 10 to 20 minutes is also performed before mill inspection or relining The complete grindout is required to obtain the accurate ball load measurement or the percentage by volume of balls in the mill This is usually performed soon after a crash stop The basic principle is to measure theOptimization of mill performance by using SciELO

Review Article A comparative study on the effects of dry and

2019年9月1日 In terms of the energy consumption (EC) for a certain particle size distribution, several investigations reveal that in dry grinding the EC is around 15–50% higher than in a wet environment [2], [10], [14], [15]Ogonowski et al (2018) conducted an investigation to compare wet and dry grinding processes in an electromagnetic mill2017年7月3日 These terms must not be confused with differential grinding, which has to do with the relative grinding rates of two or more minerals in an ore Rod Mills = Selective Grinding Ball Mills = NonSelective Grinding Large Balls Small Rods Compared Is it better to use a grinding mill with large balls or will small rods?Ball Mills vs Rod Mills 911MetallurgistBalls 4650 kg/m 3 Cylpebs 4700 kg/m 3 Rods Overloading tends to accumulate fines at the toe of the mill which results in a cushioning effect When the rock load is low, excessive balltoball contact retards the rate of breakage It has been recognized that the grindability of an ore in a ball mill is a function of both feed and mill AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill 2011年1月1日 of the ore and balls in the mill for cycles 14 and 57/8 of the Bond test procedure This gives an average measured total energy of 01331 Wh/rev “The effect of ball size on the energy Measurement of electrical energy consumption in a Bond ball mill